Traditionally, it takes complicated procedures to do the filling part. The workers have to weigh the material then fill them into the corresponding parts. But for the common scales & the manual method, the accuracy required cant be reached. Additionally, the speed is relatively slow. It takes 35 people to finish this part, so it takes a lot of labor as well. XIDO down & feather filling machine was invented to solve those problems.

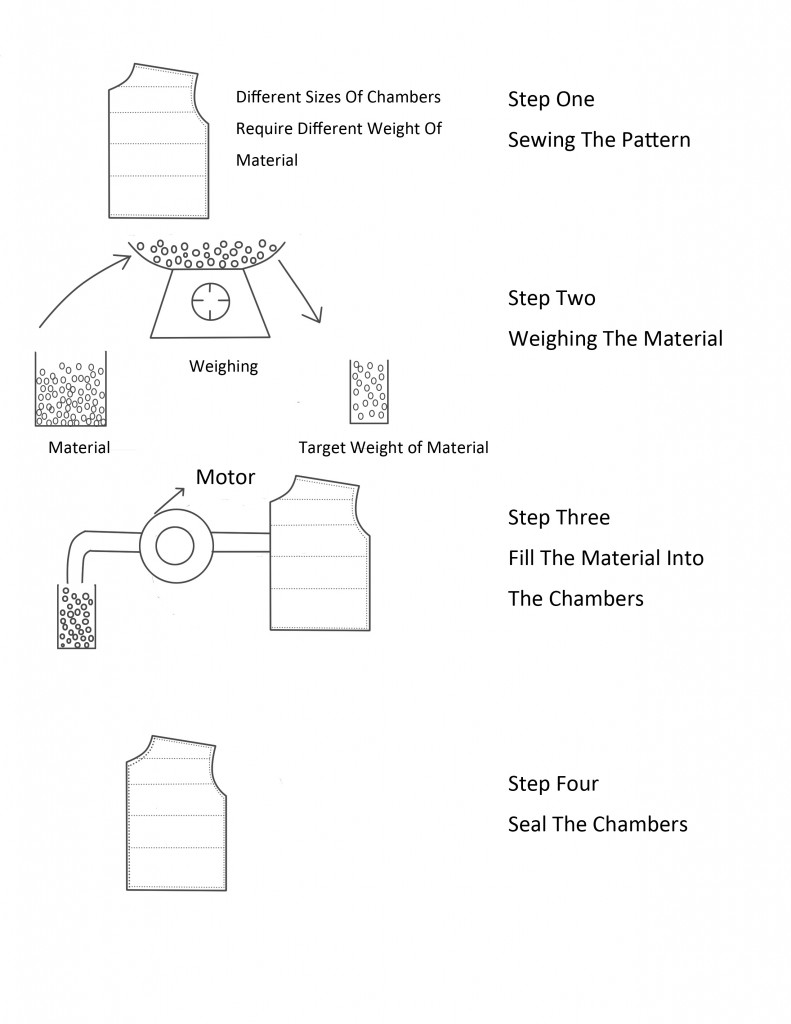

The Following Pictures Explain How Different These Two Machines Function

Manual Filling Method

Manual Filling Method

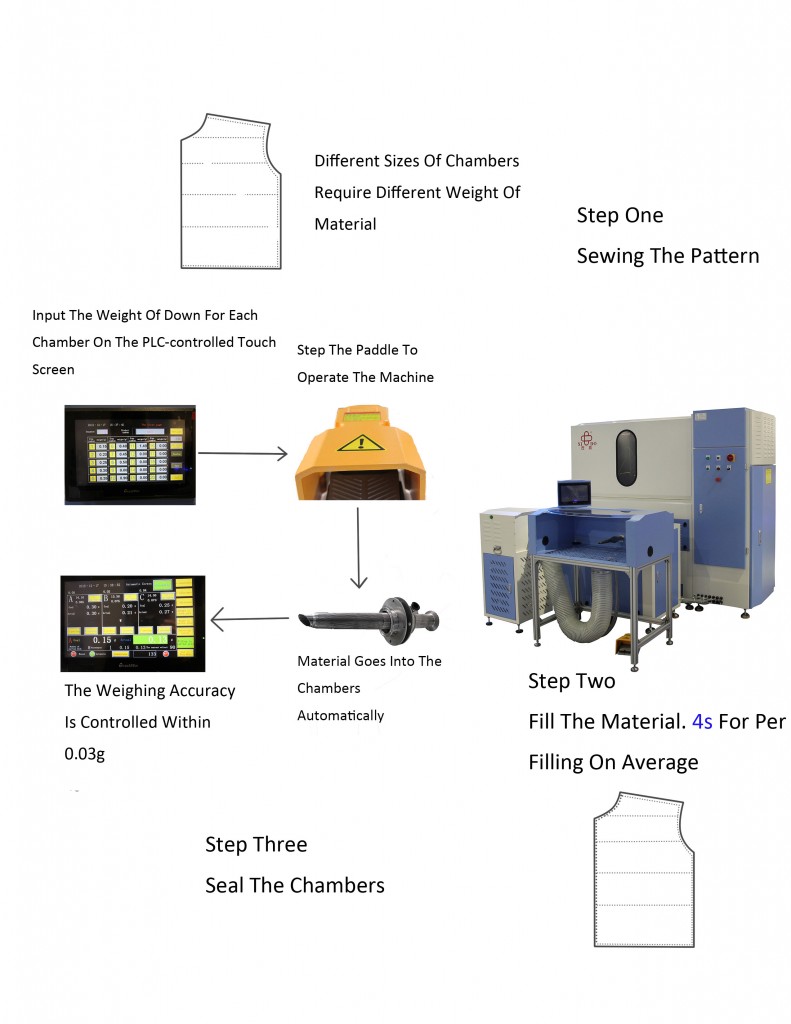

How XIDO Down & Feather Filling Machine Works

How XIDO Down & Feather Filling Machine Works

Compared to the traditional manual method , the XIDO fully automatic down filling machine has the following advantages:

- Labor-saving. One person can finish the filling part. It saves a lot of time.

- Easy-operated. With the PLC-controlled system, the machine will work automatically based on the data input into the PLC-controlled touch screen

- No need for skill workers. As the operation is easy, with simple training, any inexperienced worker can operate the machine perfectly.

- Fast Speed. 4s for per filling on average with XID fully automatic down filling machine

- High accuracy . XIDO fully automatic down filling machine is equipped with the non-contact weighing system, which guarantees the weighing accuracy perfectly.

- Environment-friendly. Every step of the operation executed in the sealed environment, which prevents the fluffy down from flying everywhere, which guarantees a clean working environment.