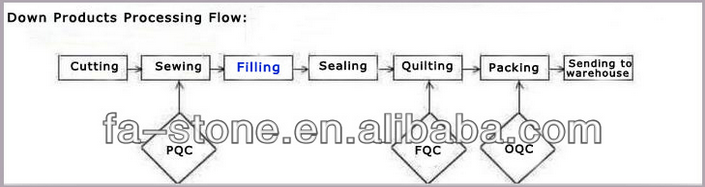

Duck Down Jacket Making Flow Chart

A down jacket product needs to go through the above processes to be made. Among these processes , the filling process is the most difficult one.Because it is hard to balance the filling speed and the down quantitative precision at the same time. With the manual method, only skilled workers can do a much better job. However, skilled workers are rare and it takes years of practice for an Inexperienced worker to be a skilled down filling master.

X IDO Fully Automatic Down Jacket Filling Machines are created to solve the problems bothering the down product manufacturers during the down filling process.

Duck Down Jacket Advantages:

The Down Filling Machine is Highly efficient. The triple-weighing system enables contious high-speed filling

The Down Filling Machine is Labor-saving.Every single port is operated by one person and the can supply2-3 assembly lines.

The Down Filling Machine has High quantitative precision, 0.03g can be reached

The Down Filling Machine is Fully-automatic and easy-operated

The Down Filling Machine is Environment-friendly. The whole process is proceeded in the sealed space, which guarantees theclean working environment.

Quality guaranteed. The important parts are imported from the best suppliers abroad.

Duck Down Jacket Display:

The Whole Set of Goose Down Filling Machine Looking From The Side Angle

The Touch Screen Which Can Save Up to 100 Data Enabling Both

Single Quantity Filling And Multiple Quantity Filling

The Paddle. Finish A Whole Intact Filling With One Paddle

Duck Down Filling Machine Has Filling Nozzle With Good

The Spare Parts. The Key Parts Are Imported From The Best Supplier Abroad

Working Principle of Goose Down Jacket Filling Machine

High-pressure air is used to absorb the down through the automatic weighing device and to fill the panel with a preset weight of down.

Down 60/40 up

Parameters of XIDO Down & Feather Filling Machine

|

Model No. |

SCR-2P-6G |

Voltage |

220V 50Hz |

|

|

Dimensions |

4.3m×2.1m×2.1m |

Power |

Filling Machine |

1.5 kW |

|

Air compressor |

7.5 kW |

|||

|

Filling Material |

Down 60 Up |

Min Operating Air Pressure |

0.58 MPa |

|

|

Filling Speed |

4 g/s (adjustable) |

Weighing Ability |

0.1-25 g |

|

|

Filling Port |

2 Pcs |

Filling Accuracy |

± 0.05g |

|

|

Efficiency |

2~4 times than manual |

Down Storage Volume: |

8KGS |

|

|

N.W/G.W |

650kg/1000kg |

Min Operating Space Size |

4×6 m |

|

Goose Down Jacket Filling Machines Receive One Hundred Percent Of Good Feedback From Our Clients

Pictures Taken From One Of The Largest Uniqlo Down Jacket OEM Factory In China

Goose Down Filling Machine Patents & Certificates

Products At Exhibitions

Pre-sale Service:

We provide our customers with 24 HOURS telephone consultation service, and will make response and arrange service within 24 hours in respect of the service request made by the customer through telephone, letter, fax, e-mail or online submission.

After-sale Service:

*Main parts apply SIEMENS, SCHNEIDER, DELTA, could live long. And the quality is rlaible and stable.

*High quality, low maintenance rate

*Make each part standard, could change for you easily

*Technicians help setting up and training workers till they could operate well